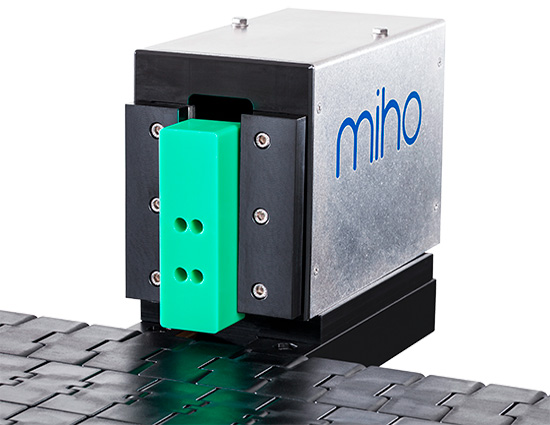

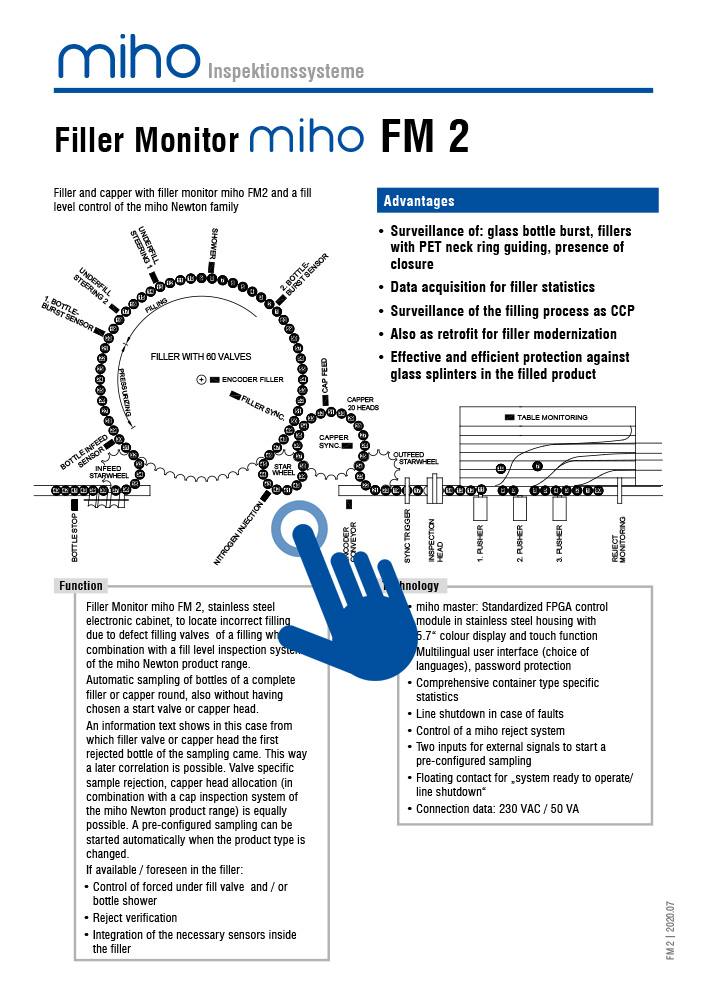

Filler monitor miho FM 2

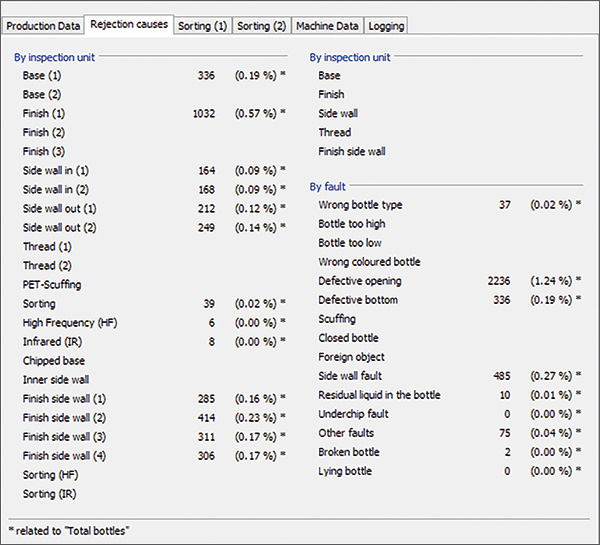

Inspection device for installation in the filler. Determines whether each individual filling valve of the filler carousel has filled without error.

The filler monitor is best connected to a fill level control and can be retrofitted to almost any filler.

Filler Monitor miho FM 2, stainless steel electronic cabinet, to locate incorrect filling due to defect filling valves of a filling wheel in combination with a fill level inspection system of the miho Newton product range. Automatic sampling of bottles of a complete filler or capper round, also without having chosen a start valve or capper head. An information text shows in this case from which filler valve or capper head the first rejected bottle of the sampling came. This way a later correlation is possible. Valve specific sample rejection, capper head allocation (in combination with a cap inspection system of the miho Newton product range) is equally possible. A pre-configured sampling can be started automatically when the product type is changed.

If available / foreseen in the filler: Control of forced under fill valve and / or bottle shower

• Reject verification

• Integration of the necessary sensors inside the filler